Introduction to the Test

Machine safety and risk assessment are a series of logical steps in which the risks associated with the machinery can be systematically analyzed, determined/resulted, and evaluated.

A manufacturer or the authorized representative of the manufacturer should carry out risk assessment to determine the Essential Health and Safety Requirements applicable to the machinery. After risk assessment, it is necessary to repeat the process of substantially eliminating hazard and reducing risk whenever necessary and implementing protective measures.

Risk is also caused by misuse of machinery, products, and parts used. Therefore, Machinery safety should be proved through test in accordance with standards.

The ICR's experienced engineers perform safety and risk assessments and provide services to the required test.

Applied field

1.Risk assessment

2.Electrical Safety Test

- Earthing Continuity Test, Insulation Resistance Test, Dielectric Withstand Test, Protective against residual voltages Test, Functional Test

3.Electromagnetic Compatibility Test(On-site Test)

- Electro Magnetic Interference Test(EMI)

- Electro Magnetic Susceptibility Test(EMS)

4.Noise measurement Test

5.Load Test

6.Semiconductor equipment Test

- Electrical Safety Test, Chemical Test, Sag Test, Static electricity, etc.

Affected product

Machine tools: Lathe, Milling machine, Roller machine, Press, Injection molding machine, etc.

Transport machine: Electric forklift truck, Crane, Conveyor, Lift, etc.

Semiconductor • LCD Manufacturing Equipment: CVD, Etch, Inspection, PVD, etc.

Automatic equipment: Robot, Printing machine, Welding machine, Marking, Inspection, Packing, etc.

Other Industrial Machinery • Apparatus: Aerial work platforms, Crusher, Food processing machine, etc.

Industry sector

Test Standard

Risk Assessment

- EN ISO 12100

Electrical Safety Test (Earthing Continuity Test, Insulation Resistance Test, Dielectric Withstand Test, Protective against residual voltages Test, Functional Test)

- EN 60204-1

Electromagnetic Compatibility Test(On-site Test)

EN 61000-6-2 / EN 61000-6-4

EN 61000-4-2 / EN 61000-4-3 / EN 61000-4-4 / EN 61000-4-5 / EN 61000-4-6 / EN 61000-4-8 / EN 61000-4-11

EN 55011

EN 50121-3-2

S2-W-5

Noise measurement Test

- EN ISO 11202

Load Test

- EN 1493

Semiconductor equipment Test

- Electrical Safety Test: SEMI S2

- Chemical Test: SEMI S6

- Sag Test: SEMI F47

- Static electricity: SEMI E78

Test equipment

Electrical Safety Test

Electromagnetic Compatibility Test(On-site Test)

EMI Test Receiver

L.I.S.N

ESD Generator

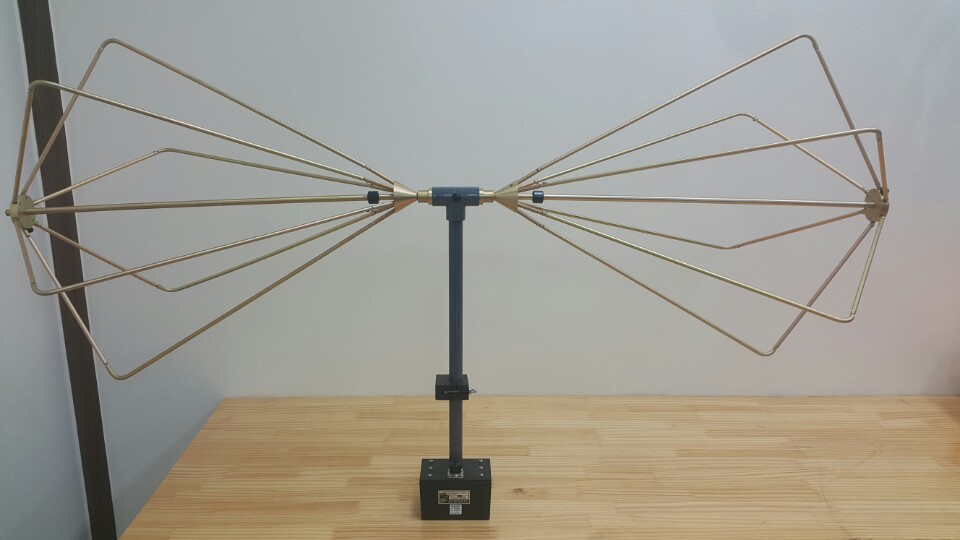

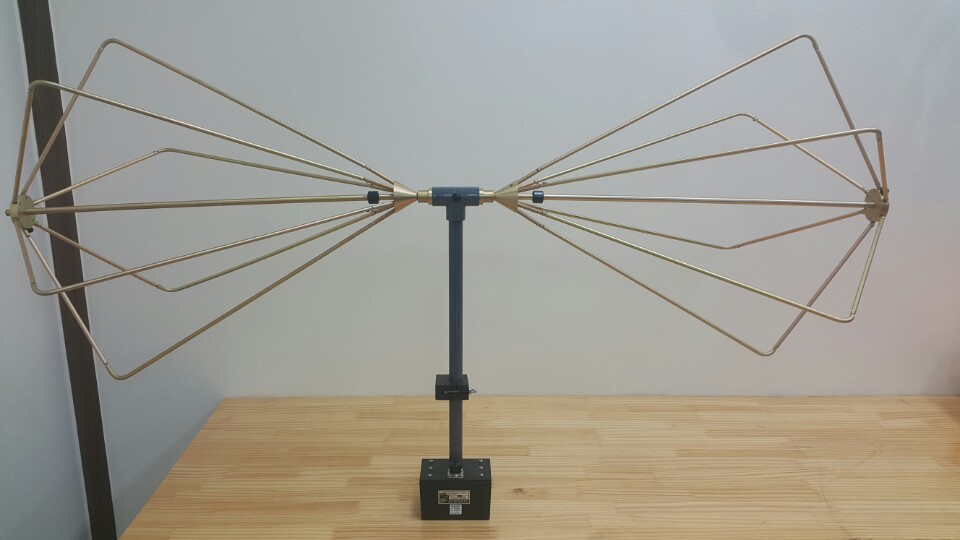

Biconical Antenna

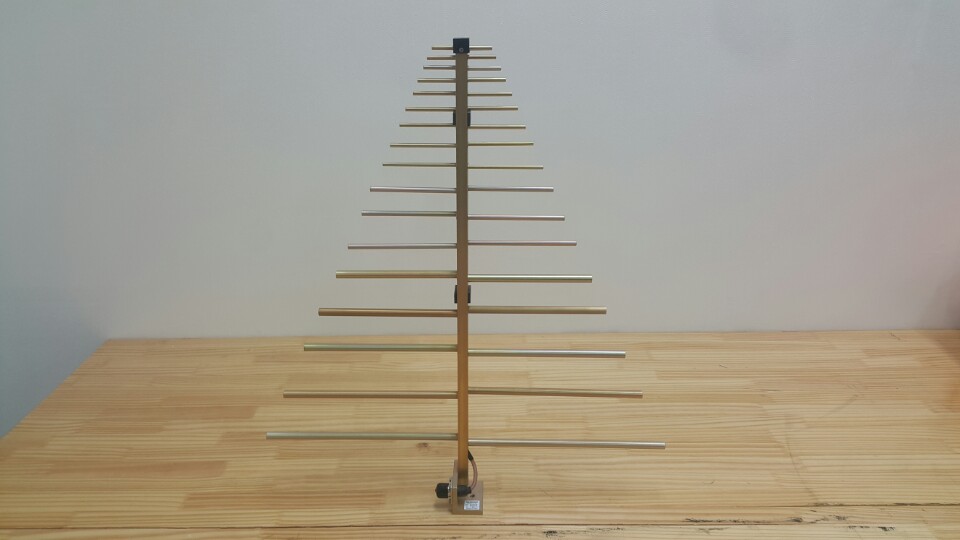

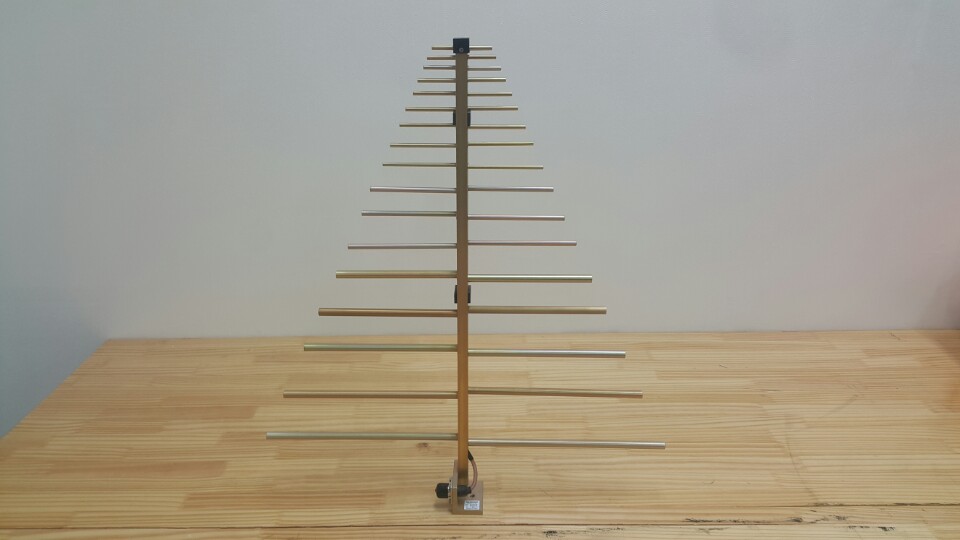

LOG Period Antenna

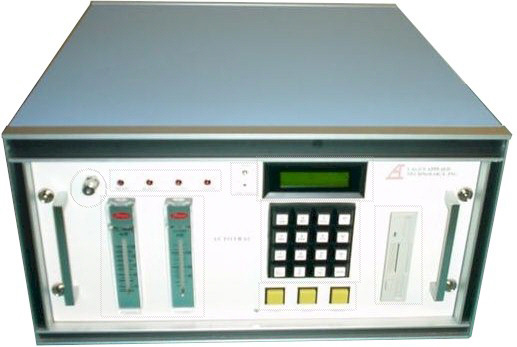

EMS Test simulator

Signal Generator

Power Amplifier

BCI Probe

Capacitive Clamp

Three phase CDN

Noise measurement, Semiconductor Equipment Test

Noise measurement test – Sound Level Meter

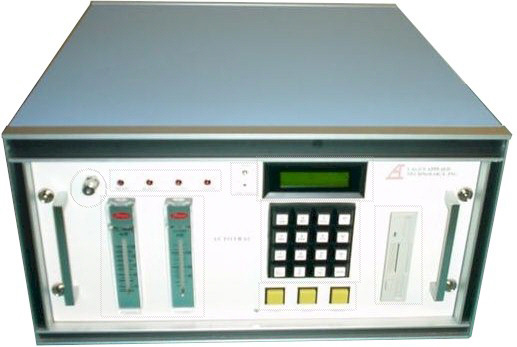

Chemical test – AutotracTM

Sag –Voltage Sage Generator

-

Contact Person

- Kang Kyung Man

-

kkm@icrqa.com