ISO 9001 is a family of standards established by ISO (International Organization for Standardization) that relate to quality management systems and are designed to help organizations ensure they meet the needs of customers and other interested parties.

ISO 9001 was established in 1987, and currently, 2015 version of standard certificates are issue for hundreds of thousands of organizations all over the world. ISO 9001 is a system providing certification by evaluating whether a quality management system of an organization adheres to the ISO 9001 standard. The applicable fields of the standard may include all the industrial sectors covering not only the manufacturing, construction, and services, but also public service sectors such as school and local autonomy.

Through the effective approach of ISO9001, an organization can achieve the management effects as shown following.

In an age of limitless global competition with emphasis on quality assurance of products and services, confidence and product liability, all organizations providing products and services under fierce price competition and non-price competition are developing a quality management system that places a top priority on customer satisfaction. The quality management system defines all of the activities necessary to produce consistent results for the client related to the product or service offered. Policies for assuring quality are established, documented, implemented, and maintained to promote continuous improvement. Certification to the ISO 9001 standard is utilized as a method for introducing and building up the quality management system, and can expect the following interactive coupling effects.

(Reference: IAF-ISO Joint Communique on Expected Outcomes for Accredited Certification to ISO 9001)

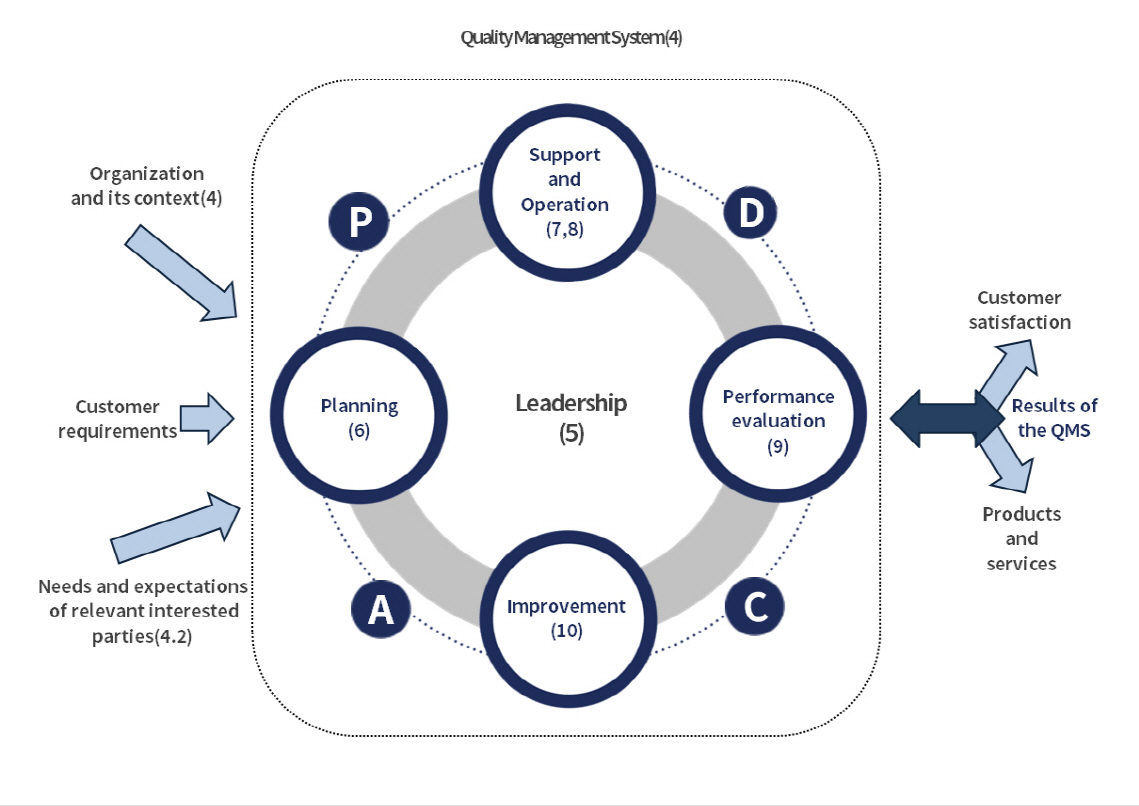

ISO 9001:2015 promotes the adoption of a process approach when developing, implementing, and improving the effectiveness of a quality management system in order to enhance customer satisfaction by meeting customer requirements. Understanding and managing interrelated processes as a system contributes to the organization's effectiveness and efficiency in achieving its intended results. This approach enables the organization to control the interrelationship and interdependencies among the processes of the system, so that the overall performance of the organization can be enhanced.

The process approach involves the systematic definition and management of processes, and their interactions, in order to achieve the intended results in accordance with the quality policy and strategic direction of the organization.

The application of the process approach in a quality management system enables:

- understanding and consistency in meeting requirements

- the consideration of processes in terms of added value

- the achievement of effective process performance

- improvement of processes based on evaluation of data and information

ISO 9001:2015 includes carrying out preventive actions to eliminate potential nonconformities, analyzing any nonconformities that do occur, and taking action to prevent recurrence that is appropriate to the effects of the nonconformity.

To conform to the requirements of ISO 9001, an organization needs to plan and implement actions to address risks and opportunities. Addressing both risks and opportunities establishes a basis for increasing the effectiveness of the quality management system, achieving improved results, and preventing negative effects.

Opportunities can arise as a result of a situation favorable to achieving an intended result, for example, a set of circumstances that allow the organization to attract customers, develop new products, reduce waste, or improve productivity. Actions to address opportunities can also include consideration of associated risks. Risk is the effect of uncertainty, and any such uncertainty can have positive or negative effects. A positive deviation arising from a risk can provide an opportunity, but not all positive effects of risk result in opportunities.

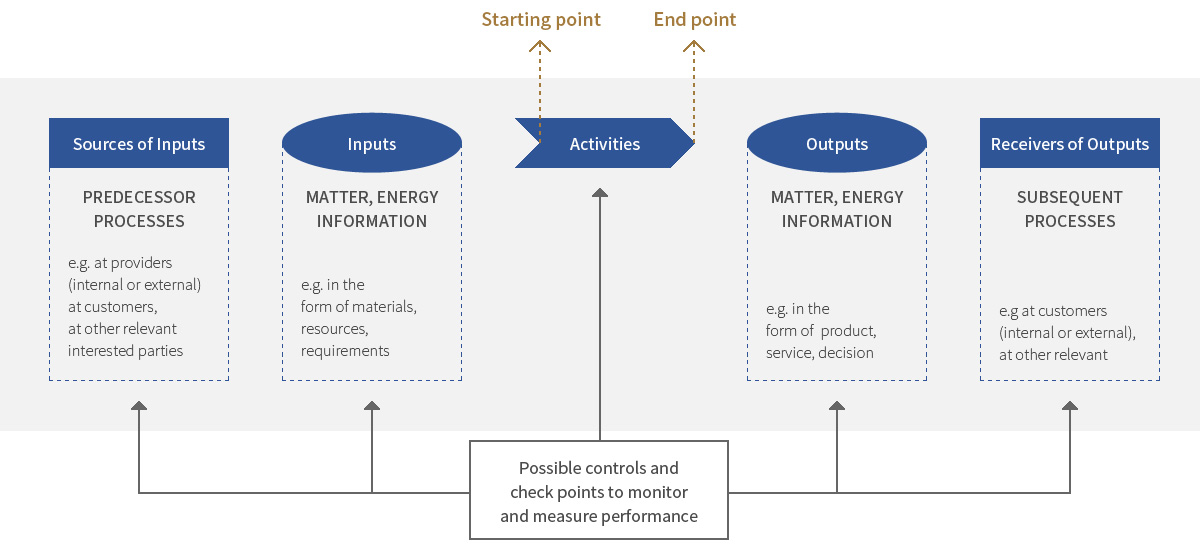

The figure below gives a schematic representation of any process and shows the interaction of its elements. The monitoring and measuring check points, which are necessary for control, are specific to each process and will vary depending on the related risks.

The ISO 9001:2008 applied the 8 quality management principles, but ISO 9001:2015 has applied the 7 quality management principles as follows.

| No. | ISO 9001:2008 | No. | ISO 9001:2015 |

|---|---|---|---|

| 1 | Customer focus | 1 | Customer focus |

| 2 | Leadership | 2 | Leadership |

| 3 | Involvement of people | 3 | Engagement of people |

| 4 | Process approach | 4 | Process approach |

| 5 | System approach to management | 5 | Improvement |

| 6 | Continual improvement | 6 | evidence-based decision making |

| 7 | Factual approach to decision making | 7 | relationship management |

| 8 | Mutually beneficial supplier relationship | - | - |

| No | Description of economic sector / activity | IAS |

|---|---|---|

| 1 | Agriculture, forestry and fishing | O |

| 2 | Mining and quarrying | O |

| 3 | Food products, beverages and tobacco | O |

| 4 | Textiles and textile products | O |

| 5 | Leather and leather products | O |

| 6 | Wood and wood products | O |

| 7 | Pulp, paper and paper products | O |

| 8 | Publishing companies | O |

| 9 | Printing companies | O |

| 10 | Manufacture of coke and refined petroleum products | O |

| 11 | Nuclear fuel | |

| 12 | Chemicals, chemical products and fibres | O |

| 13 | Pharmaceuticals | |

| 14 | Rubber and plastic products | O |

| 15 | Non-metallic mineral products | O |

| 16 | Concrete, cement, lime, plaster etc | O |

| 17 | Basic metals and fabricated metal products | O |

| 18 | Machinery and equipment | O |

| 19 | Electrical and optical equipment | O |

| 20 | Shipbuilding | O |

| 21 | Aerospace | |

| 22 | Other transport equipment | O |

| 23 | Manufacturing not elsewhere classified | O |

| 24 | Recycling | O |

| 25 | Electricity supply | |

| 26 | Gas supply | |

| 27 | Water supply | |

| 28 | Construction | O |

| 29 | Wholesale and retail trade; Repair of motor vehicles, motorcycles and personal and household goods | O |

| 30 | Hotels and restaurants | O |

| 31 | Transport, storage and communication | O |

| 32 | Financial intermediation; real estate; renting | O |

| 33 | Information technology | O |

| 34 | Engineering services | O |

| 35 | Other services | O |

| 36 | Public administration | O |

| 37 | Education | O |

| 38 | Health and social work | |

| 39 | Other social services | O |

Contact Person

kgb@icrqa.com

lee2750@icrqa.com