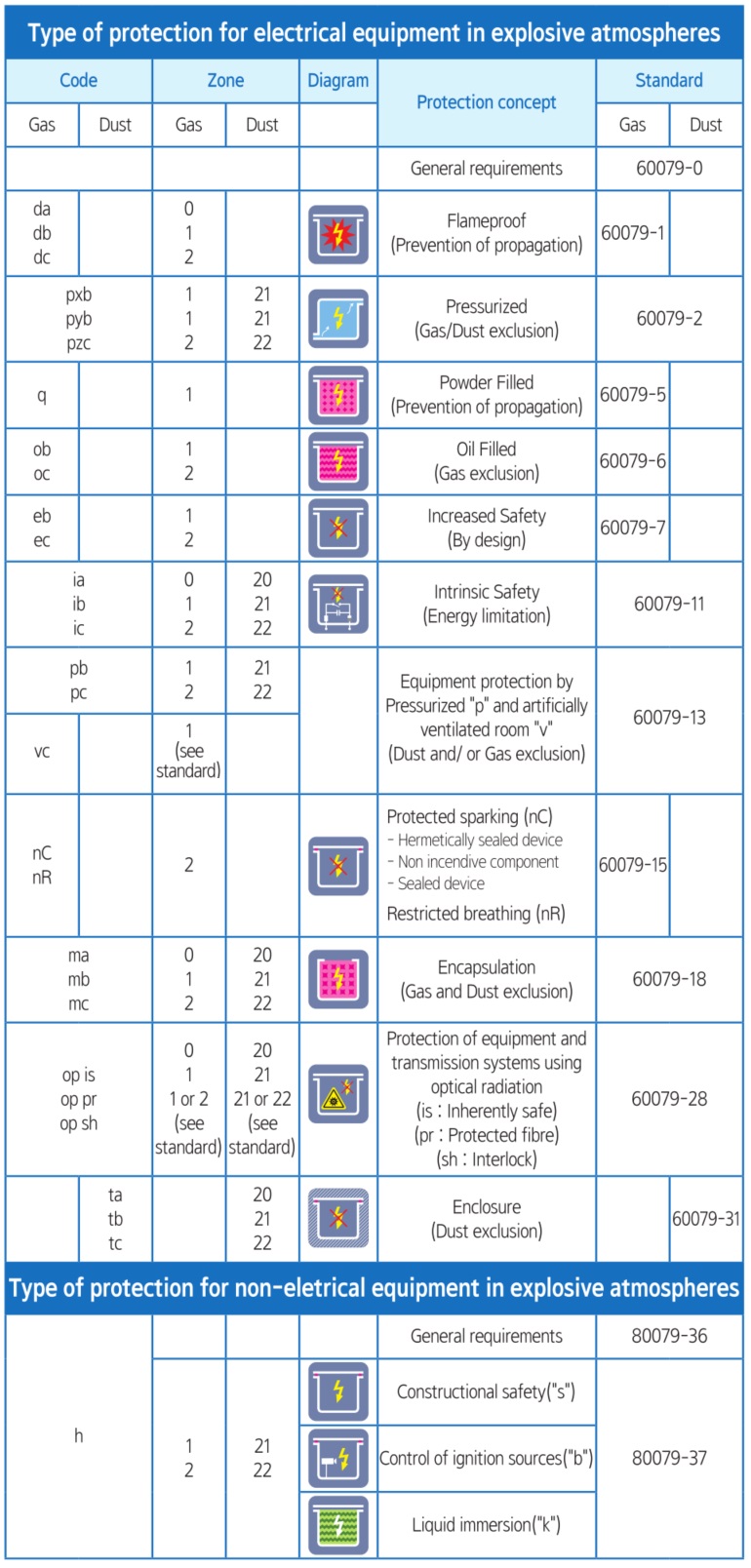

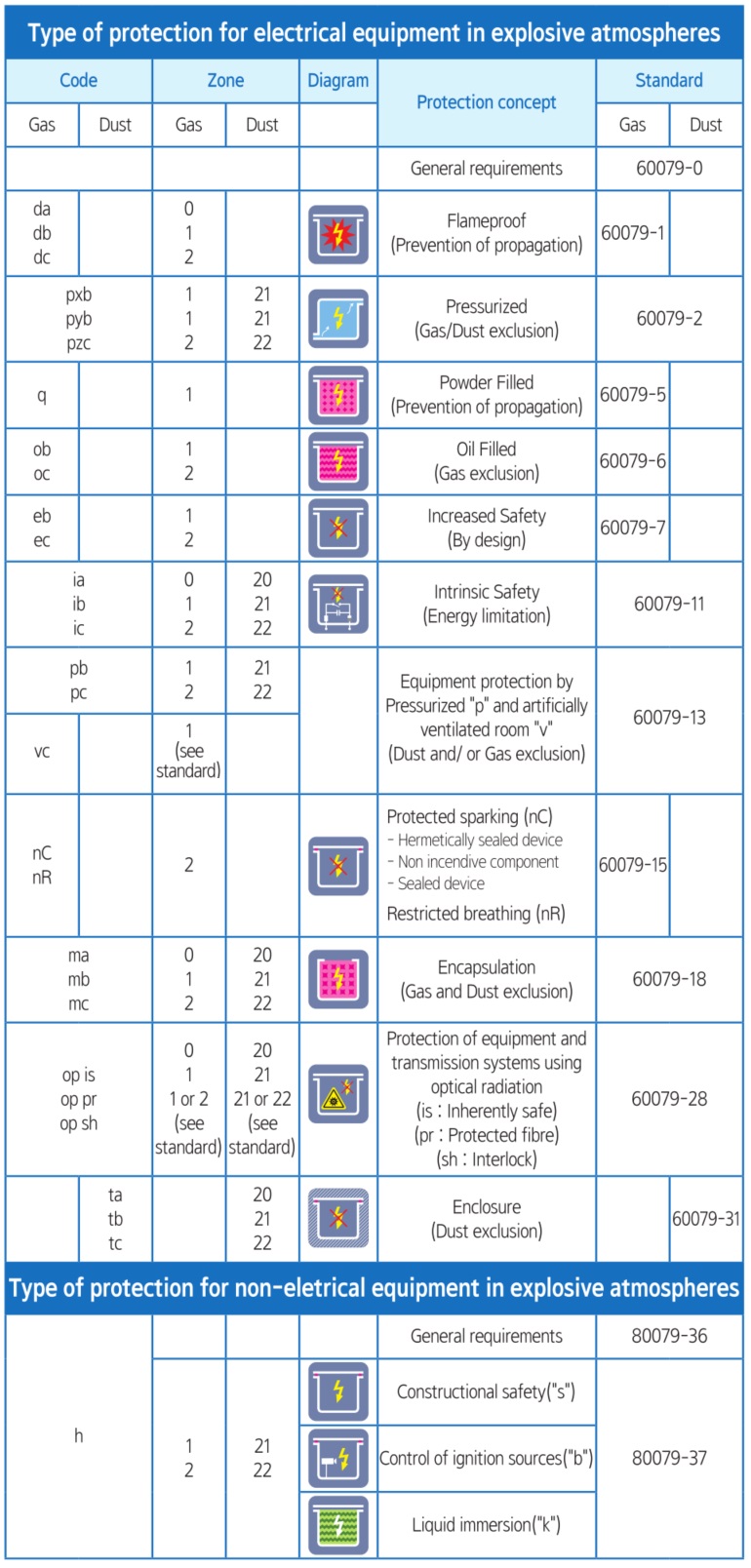

The scope of products subject to certificate is divided according to the location of manufacture, handling, or use of flammable liquids, flammable gases or dusts used at industrial sites, and is not by the product family. For example, electrical and non-electrical equipments used in mines that are sensitive to explosive gases and dust, or in areas where the atmosphere of explosive gases and dust may be formed, are eligible for Ex certificate.

Type of protection

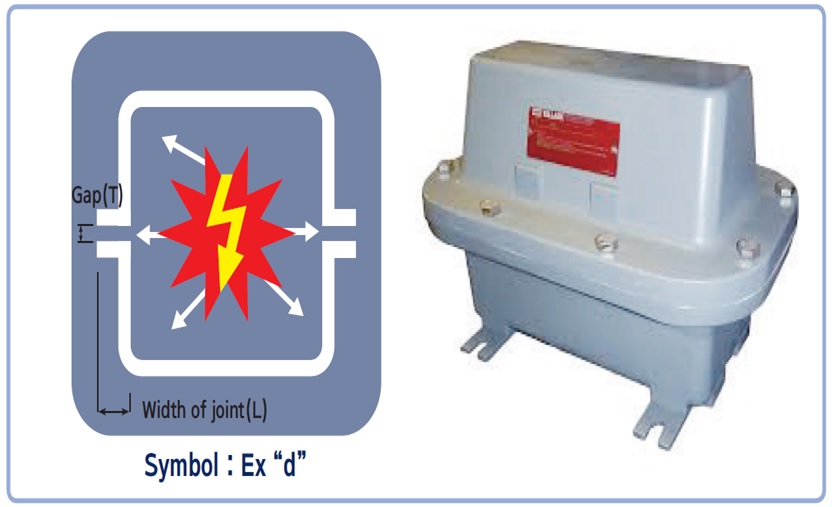

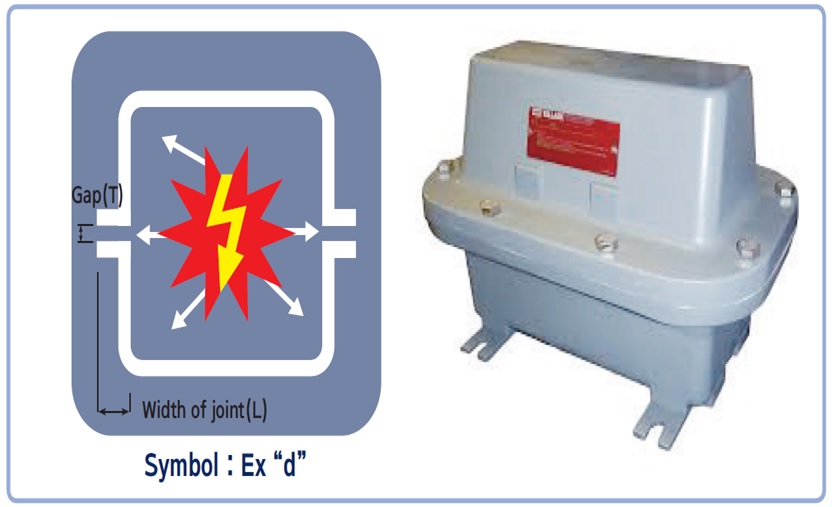

Flameproof enclosure “d”

enclosure in which the parts which can ignite an explosive gas atmosphere are placed and which can withstand the pressure developed during an internal explosion of an explosive mixture, and which prevents the transmission of the explosion to the explosive gas atmosphere surrounding the enclosure (mainly used for enclosure, motor, etc.)

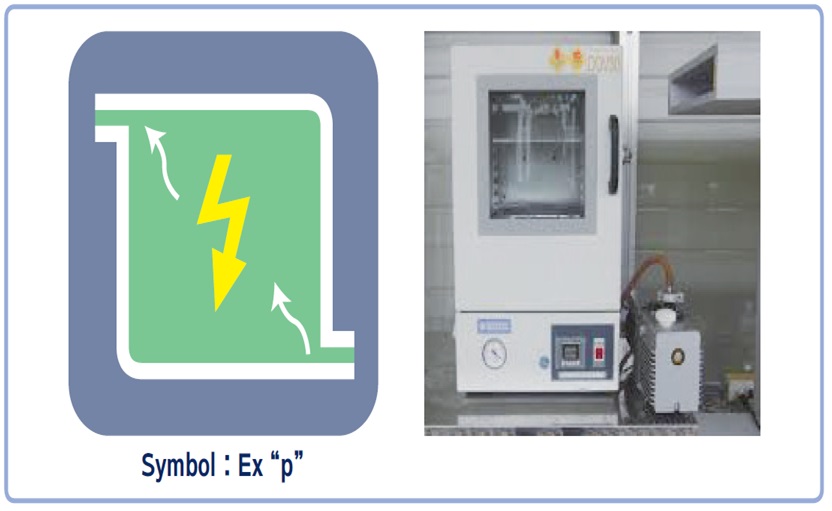

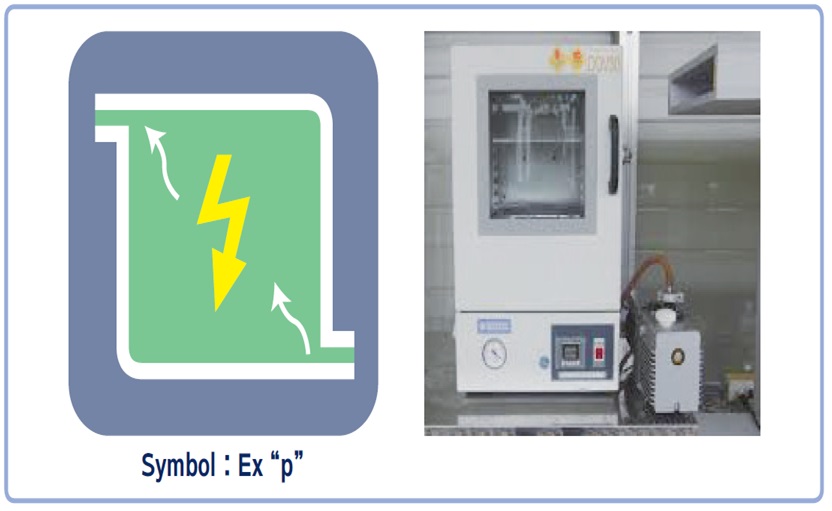

Pressurized enclosure “p”

Pressurized enclosure “p”

Structure that prevents explosive atmosphere from coming into contact with internal ignition source by diluting the inside of enclosure with overpressure or inert gas (mainly used for control panel)

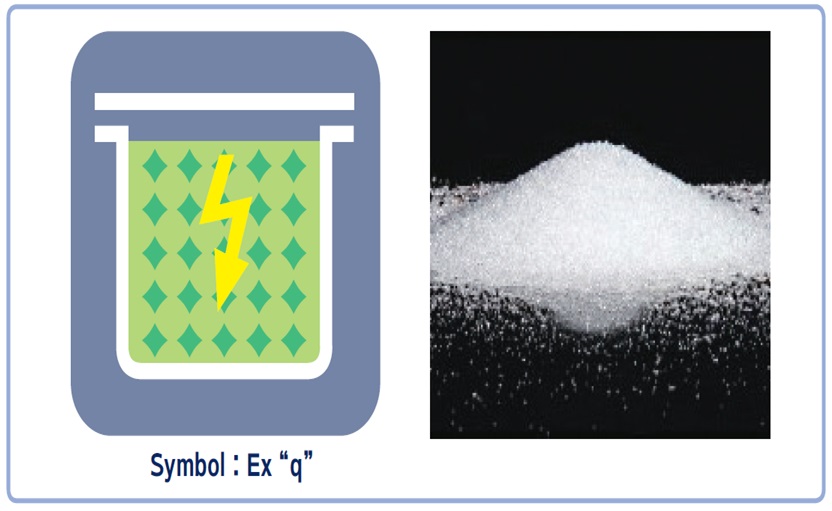

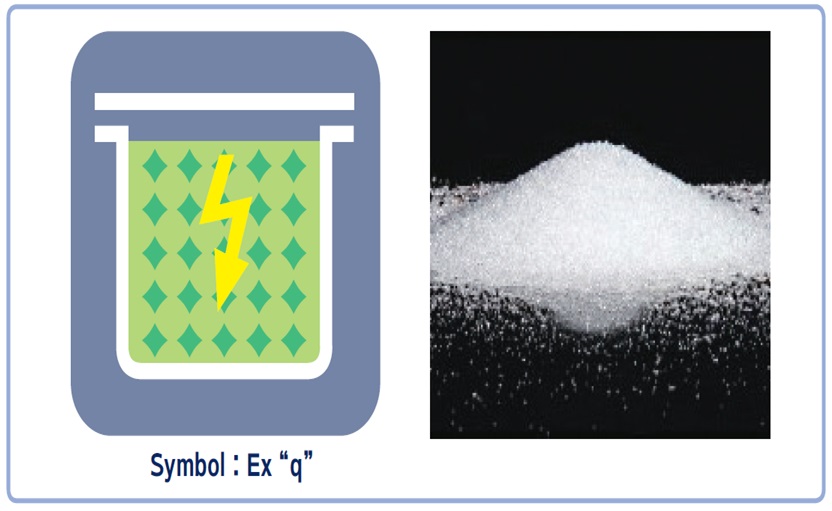

Powder filling “q”

Powder filling “q”

type of protection in which the parts capable of igniting an explosive gas atmosphere are fixed

in position and completely surrounded by filling material to prevent the ignition of an external

explosive gas atmosphere (mainly used for ignition source by electrical spark)

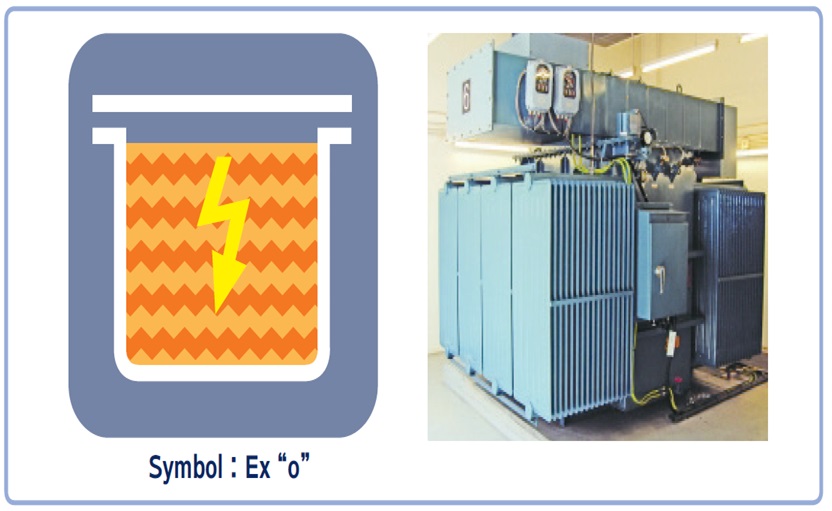

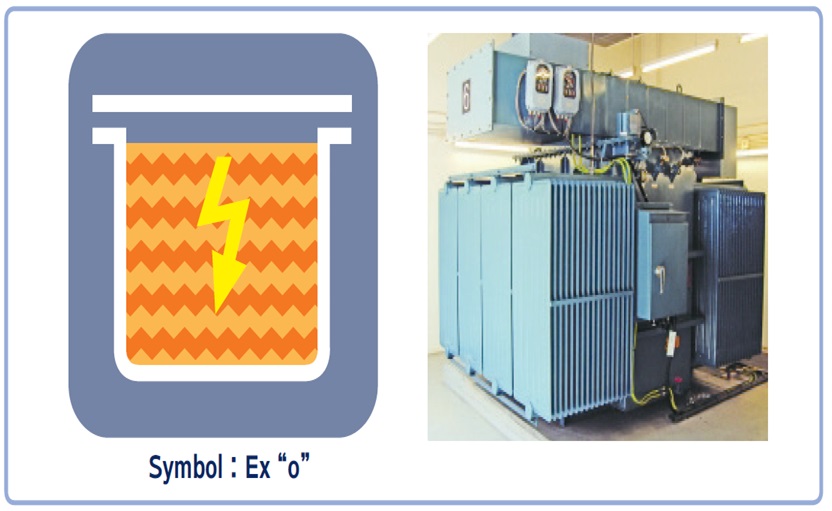

Liquid immersion “o”

Liquid immersion “o”

type of protection in which the electrical equipment or parts of the electrical equipment are immersed in a protective liquid in such a way that an explosive gas atmosphere which may be above the liquid or outside the enclosure cannot be ignited

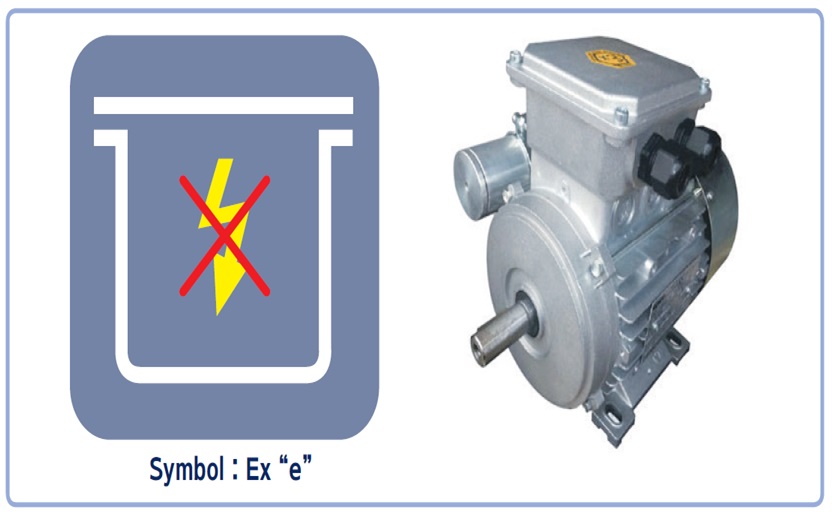

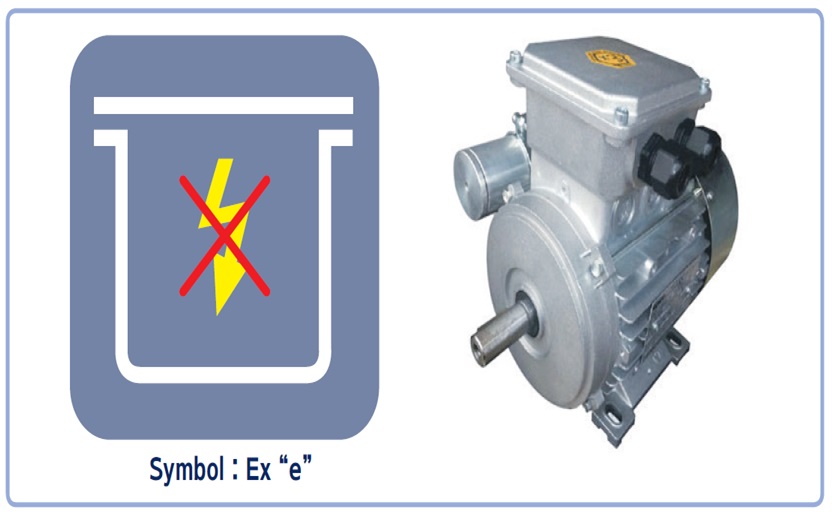

Increased safety “e”

Increased safety “e”

type of protection applied to electrical equipment or Ex Components in which additional measures are applied so as to give increased security against the possibility of excessive temperatures and against the occurrence of arcs and sparks (mainly used for motors and luminaires in zone 2)

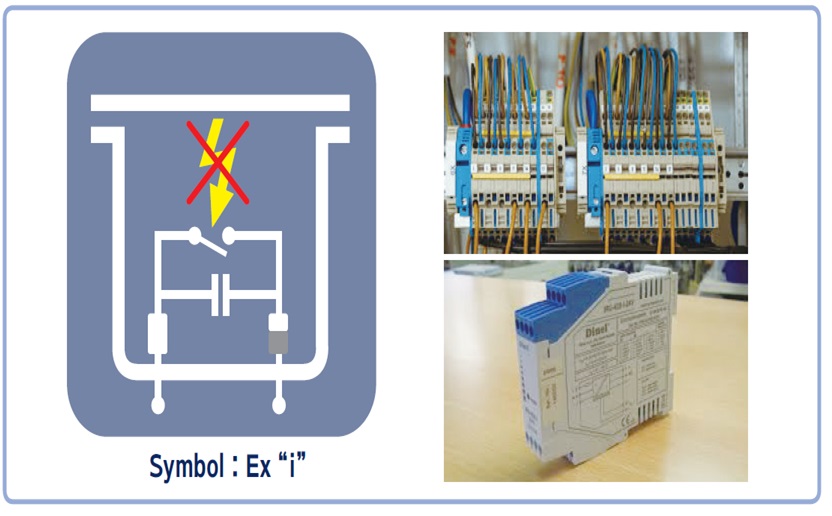

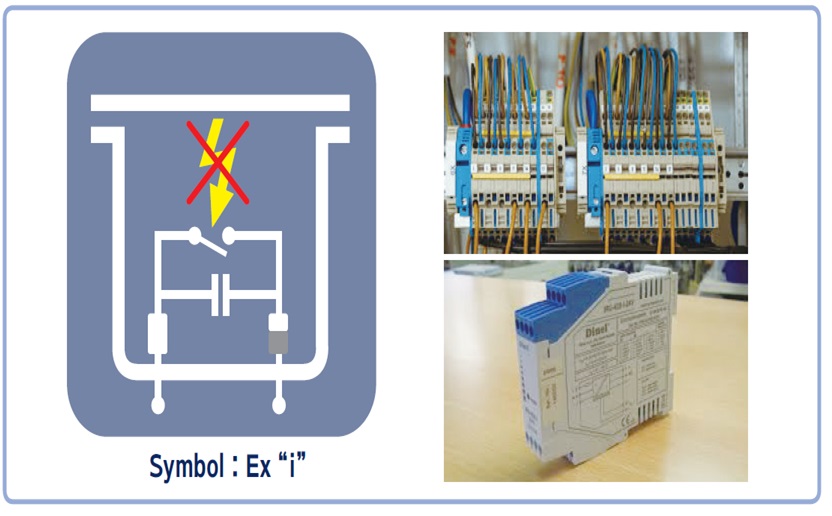

Intrinsic safety “i”

Intrinsic safety “i”

type of protection based on the restriction of electrical energy within equipment and of interconnecting wiring exposed to the explosive atmosphere to a level below that which can cause ignition by either sparking or heating effects (mainly used for low power equipments and sensors)

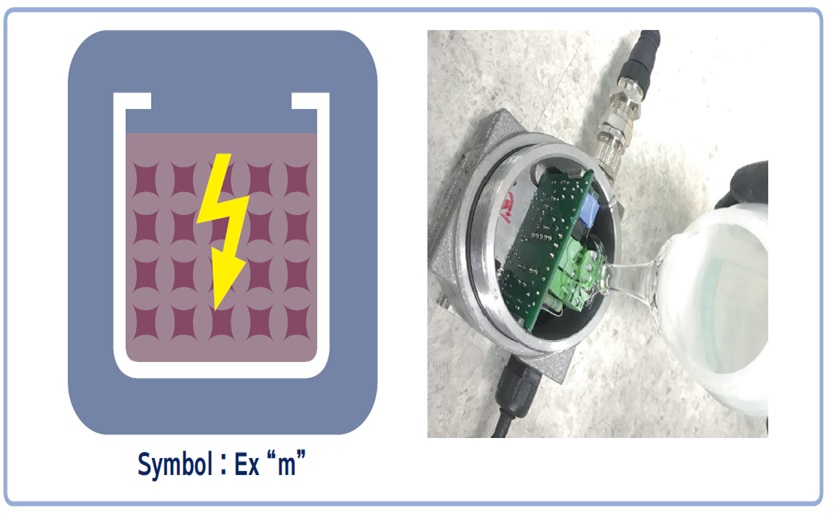

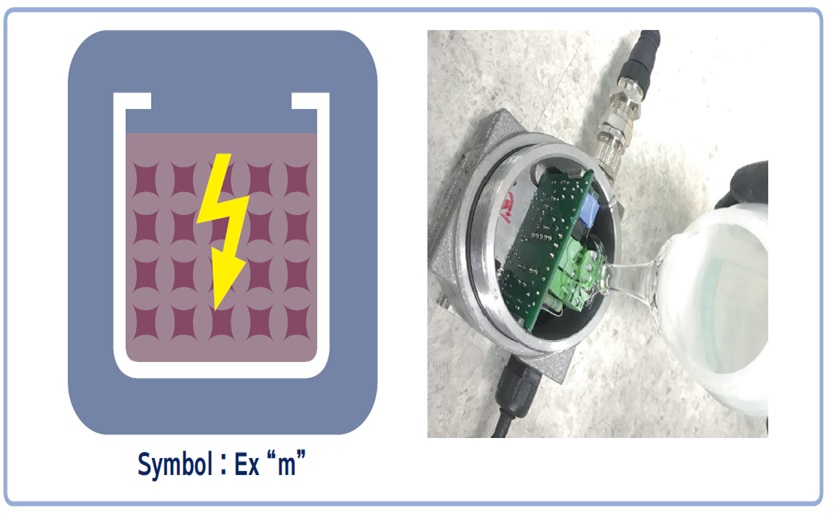

Encapsulation “m”

Encapsulation “m”

type of protection whereby parts that are capable of igniting an explosive atmosphere by either sparking or heating are fully enclosed in a compound or other non-metallic enclosure with adhesion in such a way as to avoid ignition of a dust layer or explosive atmosphere under operating or installation conditions