On 12 March 2018, ISO 45001:2018 Occupational Health and Safety Management Systems was issued by ISO (International Organization for Standardization).

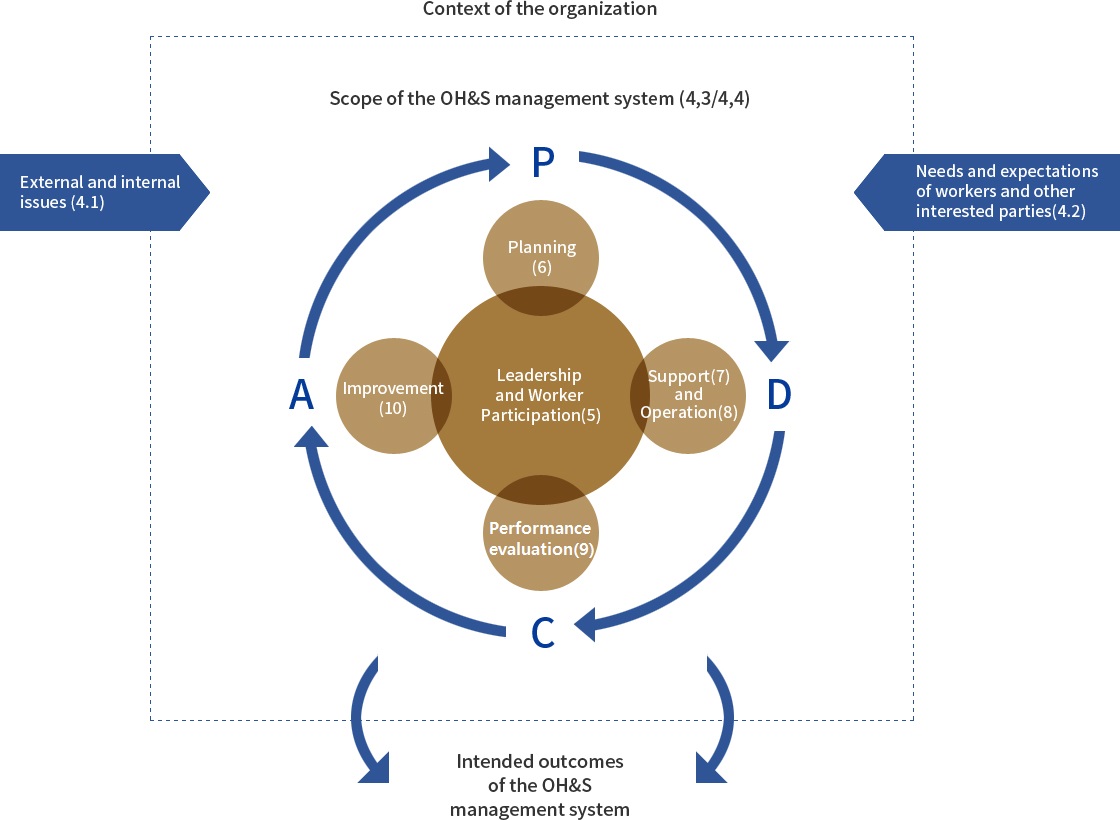

The adoption of an OH&S management system is intended to enable an organization to provide safe and healthy workplaces, prevent work-related injury and ill health, and continually improve its OH&S performance.

The purpose of an OH&S management system is to provide a framework for managing OH&S risks and opportunities. The aim and intended outcomes of the OH&S management system are to prevent work-related injury and ill health to workers and to provide safe and healthy workplaces; consequently, it is critically important for the organization to eliminate hazards and minimize OH&S risks by taking effective preventive and protective measures.

The implementation of an OH&S management system is a strategic and operational decision for an organization. The success of the OH&S management system depends on leadership, commitment, and participation from all levels and functions of the organization.

The implementation and maintenance of an OH&S management system, its effectiveness, and its ability to achieve its intended outcomes depend on a number of key factors, which can include:

| No | Description of economic sector / activity | IAS |

|---|---|---|

| 1 | Agriculture, forestry and fishing | |

| 2 | Mining and quarrying | |

| 3 | Food products, beverages and tobacco | |

| 4 | Textiles and textile products | O |

| 5 | Leather and leather products | O |

| 6 | Wood and wood products | O |

| 7 | Pulp, paper and paper products | O |

| 8 | Publishing companies | O |

| 9 | Printing companies | O |

| 10 | Manufacture of coke and refined petroleum products | O |

| 11 | Nuclear fuel | |

| 12 | Chemicals, chemical products and fibres | O |

| 13 | Pharmaceuticals | O |

| 14 | Rubber and plastic products | O |

| 15 | Non-metallic mineral products | O |

| 16 | Concrete, cement, lime, plaster etc | O |

| 17 | Basic metals and fabricated metal products | O |

| 18 | Machinery and equipment | O |

| 19 | Electrical and optical equipment | O |

| 20 | Shipbuilding | |

| 21 | Aerospace | |

| 22 | Other transport equipment | O |

| 23 | Manufacturing not elsewhere classified | O |

| 24 | Recycling | O |

| 25 | Electricity supply | |

| 26 | Gas supply | |

| 27 | Water supply | |

| 28 | Construction | O |

| 29 | Wholesale and retail trade; Repair of motor vehicles, motorcycles and personal and household goods | O |

| 30 | Hotels and restaurants | |

| 31 | Transport, storage and communication | O |

| 32 | Financial intermediation; real estate; renting | O |

| 33 | Information technology | O |

| 34 | Engineering services | O |

| 35 | Other services | O |

| 36 | Public administration | O |

| 37 | Education | O |

| 38 | Health and social work | |

| 39 | Other social services | O |

Contact Person

kgb@icrqa.com

lee2750@icrqa.com